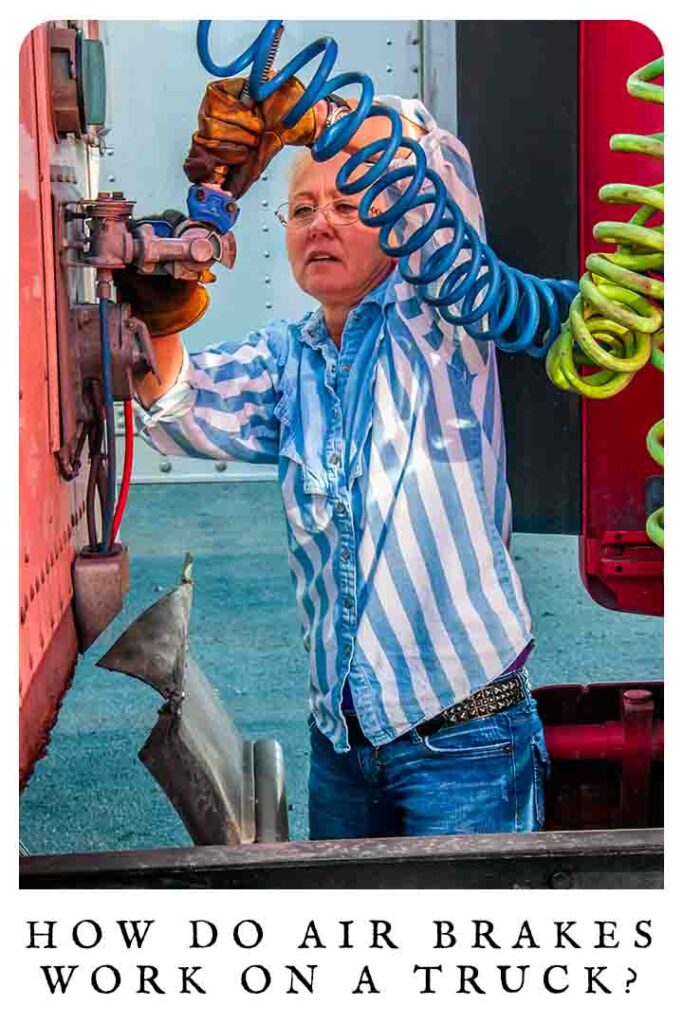

How Do Air Brakes Work On A Truck?

How do air brakes work on a truck? There are three types of air brakes, which work in slightly different ways. Although they all use compressed air to apply pressure to the braking system. The air brakes on the truck are a crucial component that ensures the safety of the driver, pedestrians, and other vehicles on the road. When the truck is hauling cargo, that puts more stress on the brake system to bring the heavy truck to a full stop. So how do air brakes work on a truck and how can you maintain them and keep them in ideal condition?

Contents

- What are air brakes?

- The three types of air brake

- Truck air brake benefits

- Air brake components

- How do air brakes work on a truck?

What are Air Brakes?

Air brake systems use compressed air to apply pressure on the brake pads to bring the vehicle to a stop. It is highly effective, especially in large vehicles such as trucks, trailers, and buses. The compressed air is stored in tanks where it becomes readily available when the driver applies pressure to the brake pedal under their foot.

The first air brakes were designed and patented by George Westinghouse in 1872. Westinghouse was a railway designer and his automatic brakes which were used successfully on trains were based on the same air brakes system he had developed earlier. When trucks became the de facto transport method of goods on roads, it was only logical that they would rely on the efficient air brakes used on trains.

There Are Three Types Of Air Brakes

Air brakes on a truck come in three types:

- Standard Air Brakes: These are available on every truck and are activated when the driver depresses the brake pedal under his foot.

- Emergency Air Brakes: This system is activated with a button on the dashboard. The button activates the air compressor to fill this emergency system with pressurized air and releases it. If there’s a leak in the air brakes, the air pressure goes down and engages the emergency air brakes.

- Exhaust Brakes: This type is available on some trucks but doesn’t use compressed air from the air compressor. Instead, it relies on the engine to function properly.

Advantages of Air Brakes on Trucks

Trucks are heavy-duty vehicles carrying heavy cargo and driving on different terrains. Sometimes the trucks drive under unfavorable weather conditions.

All of this calls for a reliable brake system that is always available, doesn’t run out or get depleted no matter how often the trucker uses it, and is easy to maintain. Air brakes check all the boxes and deliver on all of these considerations in spades.We can sum up the main advantages of air brakes on trucks as follows.

- Availability: The air brakes use compressed air and store it in tanks to apply the necessary pressure on the brake shoes and bring the truck to a stop. Air is readily available and costs next to nothing. That means that the truck will never run out of brake power.

- Low Cost: Air is free, so it makes sense that trucks would use compressed air in their brakes. This differs from hydraulic brakes that rely on costly hydraulic brake fluids to perform optimally.

- Reliability: By default, the air brakes on the truck are activated and only released when the truck is put in motion. Air compression starts at the same time the engine of the truck is started so the storage tanks will always be full of compressed air whenever the driver needs it.

- Safety: Besides being always available, the design of the air brakes system ensures that the air will not leak or lose its pressure as it is transferred from the storage tanks to the shoe pads near the tires. Unlike hydraulic brakes which fail in case of leaks, air brakes will return to their default state in cases of leaks or failure in the brake system.

Understanding the Components of a Truck Air Brakes System

To get a clear idea of how air brakes work on a truck, we need to take a closer look at the air brakes and their components. All trucks, semis, and trailers have the same air brakes system. This system contains the following components among others.

- Compressed Air Tanks: Those tanks contain the high-pressure air that applies the tremendous pressure on the brake shoes needed to bring the wheels of the truck to a stop. As long as the engine of the truck is running, those tanks will be filled with compressed air.

- Air Compressor: This small engine compresses air and pushes it into the storage tanks. It starts automatically when the ignition switch is turned on.

- Air Compressor Governor: Its primary job is to maintain adequate pressure levels in the storage tanks to ensure that the brake system is in optimal condition. When the pressurized air levels drop in the tanks, the controller switches on the air compressor to fill up the tanks.

- Brake Pedal: Also known as the foot valve. When pressed by the driver, it releases compressed air from the tanks to apply the brake pads to the wheels.

- Drain Valves: Located at the bottom of the air tanks and help to drain out water and oil that leak into the tanks.

- Foundation Brakes: They’re located behind each wheel and have different types including s-cam brakes, wedge brakes, disc brakes, or drum brakes with linings and shoes.

How Do Air Brakes Work On A Truck?

Air brakes work the same way on the truck whether it has drum brakes or disc brakes. The difference between those two brake types is in which internal parts get the pressure of the compressed air to bring the wheels to a full stop.

When the driver presses on the brake pedal with their foot, this activates the air brake system. The valves on the tanks open to release compressed air which makes its way to the brake chambers. What happens next depends on which brake system the truck has.

Drum Brakes

- The brake chambers transfer the pressure through the rod to the slack adjusters.

- The slack adjusters press on the brake cam causing it to rotate and adjust the brake shoes against the drum.

- When the shoes come in contact with the drum, the friction causes the wheels to slow down or stop.

- When the driver lifts their foot off the brake pedal, the air pressure dissipates.

- The brake shoes return to their release position thanks to the return springs. This rotates the brake cam back to its original position along with the slack adjusters. The truck can move again.

Disc Brakes

- The brake chambers activate the caliper.

- The caliper transfers the force of the compressed air to the inner brake pads which come in contact with the rotor.

- A bridge moves with the caliper to force the outer brake pads against the brake rotor.

- The pressure from the inner and outer pads on the rotor forces the wheels to slow down and stop.

- When the brake pedal is released, the return springs bring the caliper and bridge back to their release position. The brake pads disengage from the brake disc allowing the wheels to move.

Air Brakes Work With Pressure

Air brakes work through using pressure to stop your car. They are more reliable than hydraulic brakes. They’re also safer to use and don’t fail since, in cases of leaks, the emergency air brake system kicks in and brings the truck to a stop.

Know Your Truck Facts

- Why trucks smell like antifreeze sometimes

- Reasons why trucks bounce

- Truck tires that can drive over glass

- Why trucks roll onto their sides

References

- He and Jing. 2019. Study on braking stability of commercial vehicles: An optimized air brake system

- Sonawane et al. 2011. Model-based analysis of the mechanical subsystem of an air brake system

- Mahesh et al. 2021. ADVANCEMENT OF PNEUMATIC BRAKING SYSTEM